了解更多汉高业务部旗下的品牌:汉高粘合剂技术和汉高消费品牌。

点击详情2023年5月8日 Düsseldorf / Germany

Novel 1-step cure active alignment adhesive accelerates high-resolution ADAS camera assembly

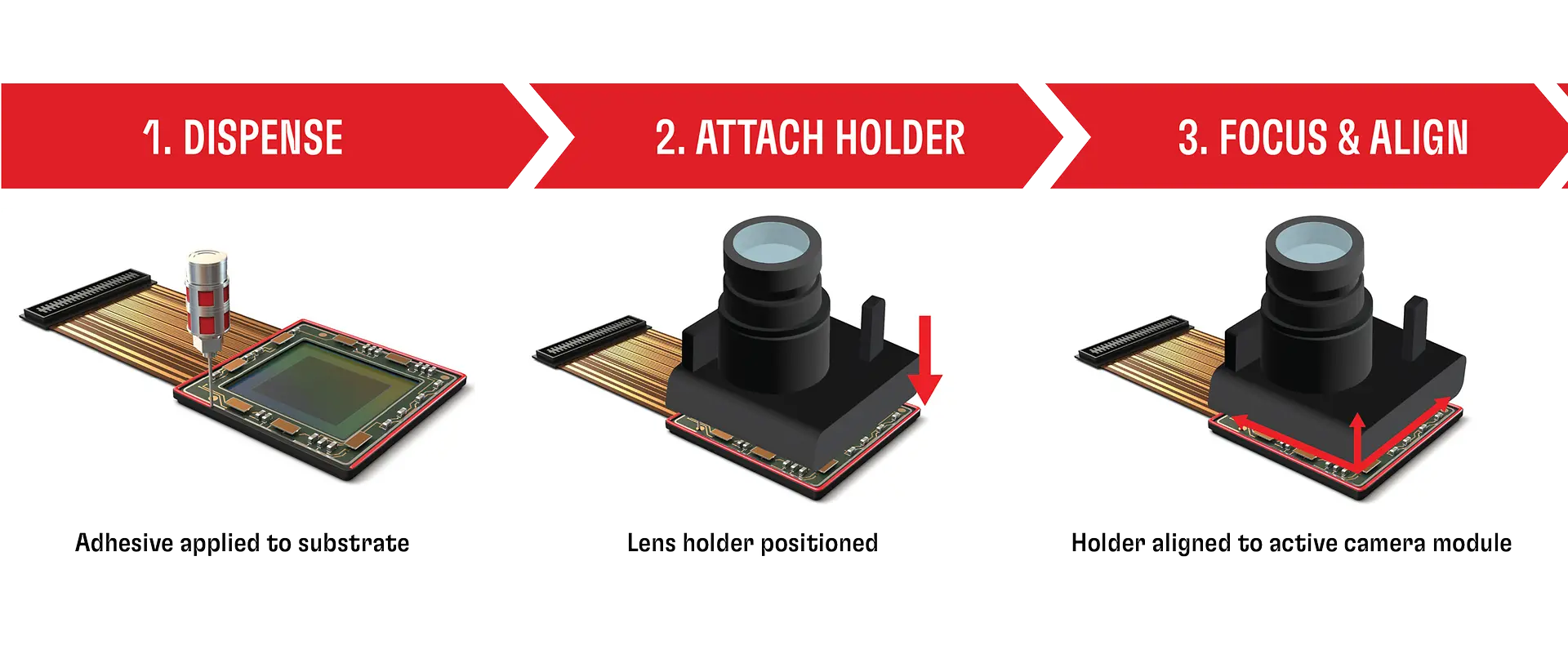

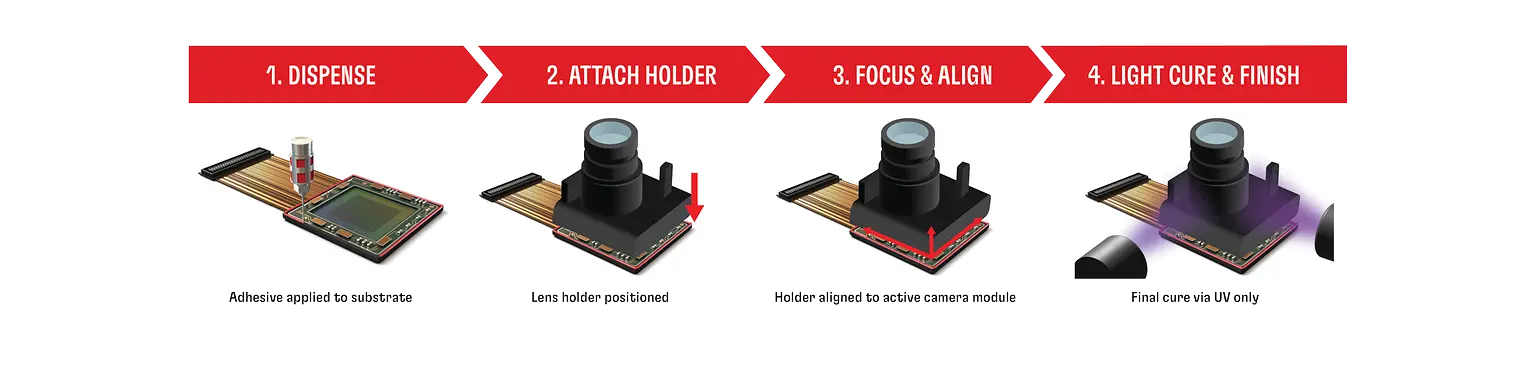

Loctite Ablestik NCA 01UV is the latest innovation that is bringing unprecedented speed, efficiency, and sustainability to the assembly of high-resolution advanced driver assistance systems ?(ADAS) camera and lidar modules. Henkel’s new active alignment adhesive can be cured in a single step with just three seconds of UV LED light exposure, circumventing the need for oven curing to save time, energy, and CO? emissions.

“As consumers expect ever more sophisticated assistance systems and increasingly depend on cameras and sensors in the context of autonomous driving, the performance and reliability of these components has become critical to road users’ safety and comfort,” explains Rodrigo Aguilar, ADAS Business Development Manager at Henkel. “As a leading partner to the automotive industry, Henkel is expanding its range of dedicated adhesives for ADAS sensor assembly – providing innovative 1-step curing that can meet the performance of preceding generations of adhesives. By enabling active alignment of ADAS sensors to within 100-nanometer accuracy, we are delivering the precision and high sensor reliability needed for vital safety functions.”

Loctite Ablestik NCA 01UV reaches its full performance and final bond strength with seconds of UV LED irradiation during the fixing step. Hence, time- and energy-intensive post-curing by oven is no longer required. By avoiding the high capital expenditure of heat cure ovens and the associated operating and maintenance costs as well as manufacturing space demands, this simpler process also makes a compelling commercial case.

By reaching excellent performance after only few seconds of UV LED cure Loctite Ablestik NCA 01UV 1-step cure adhesive meets all requirements for high resolution cameras for automotive applications, while matching its dual-cure predecessors. With low and consistent dimensional change of 0.4% during cure, this new adhesive is a reliable candidate for high resolution camera modules for automotive as no change in focus from an excessive shrinkage is to be expected. In order to meet the requirements for automotive grade for camera module adhesives, Loctite Ablestik NCA 01UV shows high reliability and dimensional stability, as well as no outgassing from volatile compounds, ensuring a high image quality and no fogging on the optical system. In line with Henkel’s commitment to developing safer and more sustainable solutions, it is free of CMT, SVHC, or any toxic substances and fully EU REACH-compliant.

Additionally, the innovative actively curing 1-step adhesive Loctite Ablestik NCA 01UV facilitates manufacturers' contribution to greater sustainability while enabling higher overall production efficiency. Eliminating the oven curing significantly decreases the duration of the entire active alignment process. This results in a more sustainable process that reduces the CO? footprint of assembly compared to a regular active alignment process. The annual energy consumption of a medium-sized oven curing an adhesive at 80° C for 70 minutes1 is equivalent to nearly 2.5 tons of CO?.2 For this amount of carbon, about 42 tree seedlings would have to grow for 10 years.3 However, the long-term cumulative effect of eliminating the curing step in a typical production site with multiple ovens will result in a significant positive contribution to sustainability.

To learn more about Loctite Ablestik NCA 01UV, click here and download the whitepaper.

1 Assuming a production rate of 240 cameras per hour, 84 kg of adhesive per year, and an oven of 11.2 meters long with a nominal power of 17 kWh using 1.6 kW to keep 80°C, and a consumption of 63 kWh per kg of adhesive, leading to a yearly consumption of about 5,300 kWh.

2 Source: https://ecoinvent.org/the-ecoinvent-database/

3 Source: https://www.epa.gov/energy/greenhouse-gas-equivalencies-calculator#results